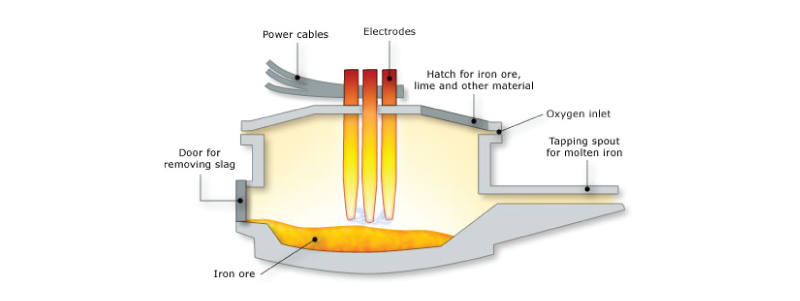

Arc Furnace

Electric melting furnaces use energy via induction to directly melt steel, brass, bronzes and nickel alloys to produce liquid metal. Induction is the process of electric or magnetic fields heating a conducting object. Two types of electric furnaces exist. One is called a direct arc furnace, and the other is called an indirect arc furnace. A direct arc furnace is composed of a cylindrical vessel that is lined. The lining is a protective layer that insulates the structure from high heat temperatures. The lining can be acidic or basic. Basic linings are used for high alloy steels. Acidic linings are used for cast irons, or scrap metal that do not need to have the element of Sulfur and Phosphorus removed. The furnace is composed of electrodes that are made of graphite or amorphous carbon. They provide the current that is needed for the induction process. The induction process is a technique used to heat metals and other electrically conductive materials by heat generated from currents. The electrodes hang vertically over the lined vessel and are powered by a transformer. The electrodes when powered produce an arc. An arc is an electrical breakdown of gas that produces a discharge. The arc is created at the end of the electrodes above the metal. The metal is then heated, and melted turning it into a molten state. From here the slag, or unusable matter, is poured from the vessel in to a separate container. The purified molten metal is now ready to be used.

A direct arc furnace is composed of a cylindrical vessel that is lined. The lining is a protective layer that insulates the structure from high heat temperatures. The lining can be acidic or basic. Basic linings are used for high alloy steels. Acidic linings are used for cast irons, or scrap metal that do not need to have the element of Sulfur and Phosphorus removed. The furnace is composed of electrodes that are made of graphite or amorphous carbon. They provide the current that is needed for the induction process. The induction process is a technique used to heat metals and other electrically conductive materials by heat generated from currents. The electrodes hang vertically over the lined vessel and are powered by a transformer. The electrodes when powered produce an arc. An arc is an electrical breakdown of gas that produces a discharge. The arc is created at the end of the electrodes above the metal. The metal is then heated, and melted turning it into a molten state. From here the slag, or unusable matter, is poured from the vessel in to a separate container. The purified molten metal is now ready to be used.

An indirect arc furnace arc occurs between two electrodes that are horizontally placed inside the vessel. The vessel of the furnace is horizontal and lined with refectories. The barrel can rotate to create uniform heating. The metal, usually copper based alloys, is heated by radiation not induction. Radiation is the transmission of heat in forms of waves through a space. The efficiency of the indirect furnace is greater than a direct furnace due to a higher power transformer and use of pure oxygen gas. Due to the high heat temperatures cooling the walls with water cooled panels is a common practice.

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

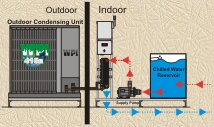

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |